Laser Profilometry on Textile Parts

Laser profilometry on textile parts – control of internal constraints

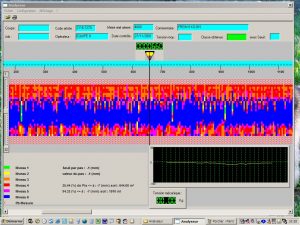

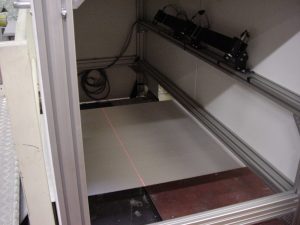

ASM has developed a high-performance laser profilometry solution for textile parts to meet the requirements of a Nice-based manufacturer specializing in technical fabrics.

Definition of the process used

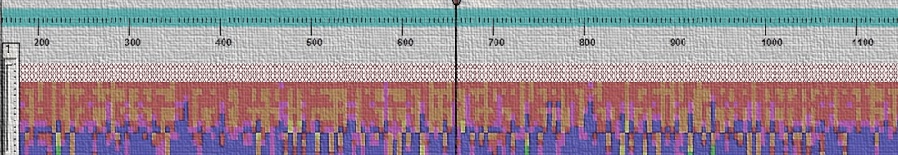

The process allows precise mapping of internal stresses induced by the weaving of glass fibers or other composite materials

A significant reduction in non-quality

This innovative technology detects manufacturing defects early, thus limiting poor quality in production. By measuring internal tensions, ASM helps its customers adjust their processes and improve the reliability of technical fabrics.

Since its creation in 1997, ASM has designed and installed more than 300 production machines, prototypes and pilot installations in France and abroad, of which here are some examples:

- Production line with 10 Universal Robots

- Robotic storage with Universal Robots

- Fully automated assembly line

- Assembly station for the high-speed medical industry

- Automated conveying, weighing and mixing for industrial perfumers