Revamping storage line with 5 UR cobots

Revamping an automated storage line with 5 Universal Robots

A leading French gold jewelry manufacturer located near Dijon had worked closely with ASM to automate the storage of its various jewelry models. The goal was both to automate stocking in automatic vertical rotary warehouses but also to automate stock removal generated by customer orders. The main difficulty of this project came from the large number of references to manage (more than 1000), packaged in plastic bags of different sizes.

Line optimization

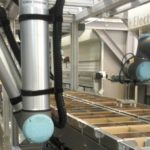

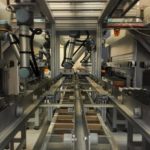

In 2020, ASM optimized the performance of this installation by replacing the Cartesian manipulation system with 5 UNIVERSAL ROBOTS in the "ceiling".

Storage Line Features

The line delivered to our customer has the following technical characteristics:

- Automated jewelry sourcing direct from manufacturing

- 5 UNIVERSAL ROBOTS robots installed in the ceiling

- Automated item weighing, bagging, labeling and storage

- Stock issue for end customer order integrated into the customer's ERP

- Integration of SCHNEIDER PLCs

- A line 28m long and 8m high, made up of 4 Electroclass cabinets with a total of 4000 drawers

ASM has designed and installed more than 300 production machines. Here are some examples of achievements that might interest you:

- A production line with the integration of 10 Universal Robots

- An automated assembly line

- Tool station

- Conveying weighing and mixing perfumes