![]() Industrial Automation

Industrial Automation

industrial automation consists in having tasks performed by machines, in order to reduce the burden on operators, while increasing productivity and improving quality.

It uses complex systems that come directly from electronics:

- Analog and digital sensors

- Programmable Logic Controllers (PLCs)

- Communication buses (CAN, CANopen, Profibus, etc.)

- 2D or 3D vision

The ultimate goal is to “replace” humans for repetitive and painful tasks, which is why automation is increasingly associated with robotization.

The key element of automation, however, remains the automaton. This programmable electronic device processes the information received from the input sensors, from the instructions and from its program to send orders by sequential processing.

A PLC is distinguished from a computer by its characteristics which perfectly meet the needs of industrial automation:

- Robustness: designed to work in hostile environments (hardened circuits to withstand temperature and/or vibrations)

- Responsiveness: optimized processing of information, code and instructions

- Easy maintenance: easy module changes and quick restart

- Identified inputs for sensors, push buttons, software instructions, etc.

- Identified outputs for indicator lights, valves, cylinders, actuators, etc.

![]() Our Skills in Automation

Our Skills in Automation

Our automation design office works with the biggest manufacturers of programmable logic controllers. Depending on your needs, those of your maintenance department and your operators, ASM is able to program any type of PLC.

Of course, depending on your needs, the ASM team will adapt and will be able to offer you individualized solutions to optimize your new production tool.

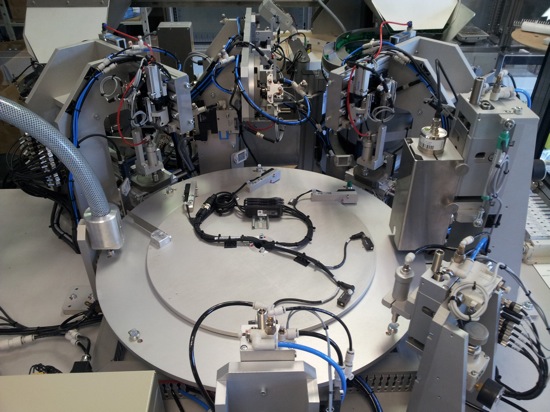

![]() Our Automated Systems Solutions

Our Automated Systems Solutions

In addition to its expertise in industrial automation, ASM can develop communicating interfaces that will allow you to improve your production tool. These exchanges of information via supervision by dedicated dashboards, the integration of your production tool into your ERP and/or your GPA or even web access by your maintenance department will make it possible to significantly improve the efficiency of your tool. of production.

| Monitoring Tools | Integration with ERP / CAPM | Embedded Web Server with Remote Access |

| Fully Automated Assembly Line | Automated Assembly Station | |

|  | |

| Our client, European leader in sanitary equipment, contacted ASM to design a line… | ASM has designed for one of the world leaders in single-use medical equipment… | |