Assembly Machines in Industry

A machine is a mechanical assembly capable of using energy to perform tasks that can be classified into 4 main categories:

- Using a tool and/or sensor

- Moving a load

- material to shape

- Information to be processed

Their operation can be carried out under the guidance or not of an operator and in industry, the machines are generally fixed.

The design and production of industrial assembly machines require multidisciplinary know-how:

- Robotics: integration and programming

- Automation: use of programmable logic controllers

- Mechatronics: management of mechanical, electronic and IT issues

The rise of machines began with the industrial revolution of the 19th century.th century and the birth of industrial automation. The advantages sought then are still relevant and recent technical progress has further improved their characteristics:

- Increase in quantities produced

- Cost reduction

- Quality improvement

- Reinforcement of operator safety

- Improved workstation ergonomics

- Versatility of machines and assembly lines

- Reduced energy needs

- Reducing the ecological footprint of products and machines

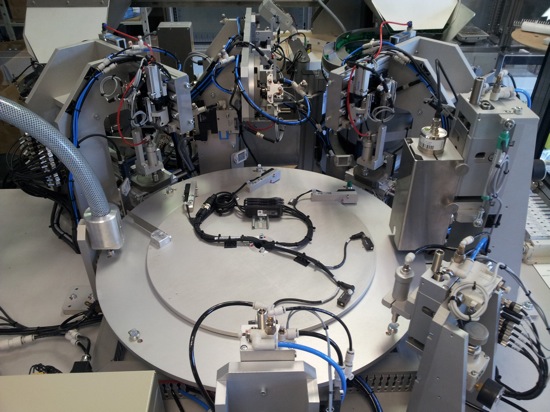

Our Assembly Machine Skills

Since its creation in 1997, ASM has specialized in assembly machines, making this area its core business. Thanks to its design office with dual expertise in Mechanical and in Automation, the company is able to meet the highest demands of its customers. With its experience in different sectors of activity, ASM offers a varied and high-quality know-how.

Our assembly machinery are designed to meet a wide variety of needs:

- From semi-assisted workstation to the fully automated assembly and test line

- For some unique pieces to more complex products with many parts to be assembled

- From the "quasi-constant" part (i.e. with very precise tolerances and dimensions, as for metal parts) to the more random product (with variable characteristics linked to the manufacturing process or the environment of production, such as in food products)

- Up to high production rates

- With manual settings or with self-adaptive software pre-configurations

- From filling simple in bulk at the line outlet up to unitary and serialized packaging

- From marking by screen printing RFID chip programming

- From manual dispensing to vibrating bowls combined with vision and robots

- From pneumatic jack up to the latest generations of robots

We make every effort to offer assembly machines that meet the specific needs of our customers, combining technical expertise, innovation and quality.

Our Achievements of Assembly Machines

With its design offices in mechanical design and automation, ASM's expertise ranges from the assembly station to the fully automated assembly line. Complex tools and dedicated test benches can also be specifically developed if your needs require it.

| Fully Automated Assembly Line | Automated Assembly Station | assembly station |

|  |  |

| Our client, European leader in sanitary equipment, contacted ASM to design a line… | ASM has designed for one of the world leaders in single-use medical equipment a special machine for… | Semi-automated station which had the particularity of adapting to a chassis predefined by the customer, in order to… |