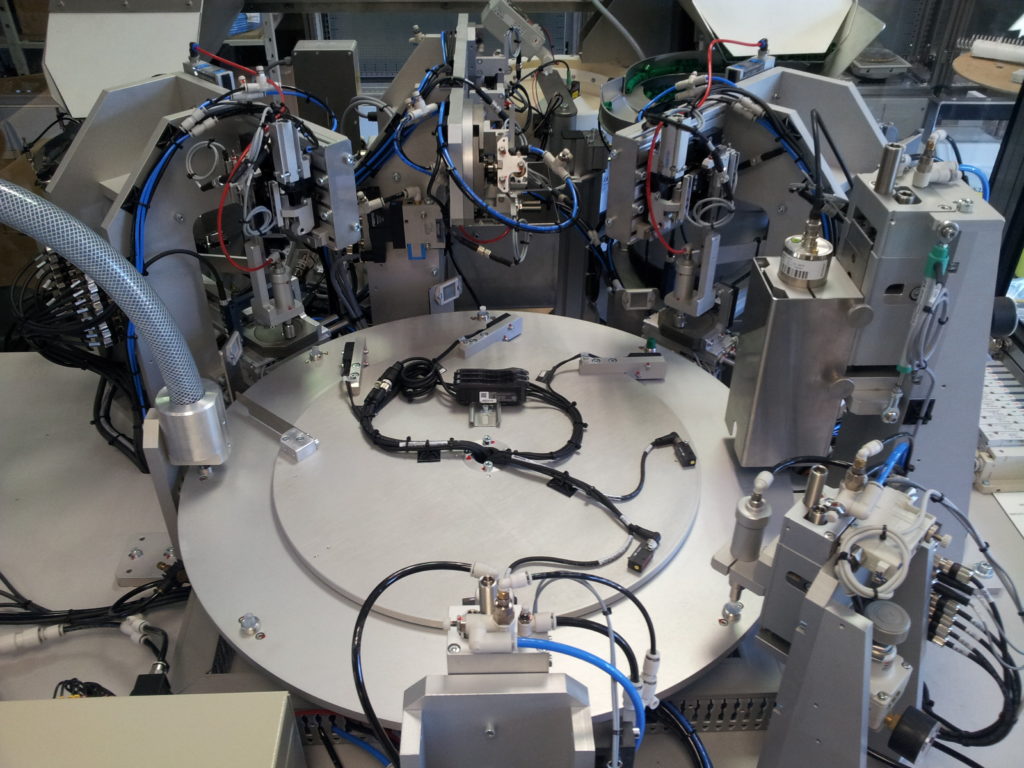

Automated medical valve assembly machine

Fully automated valve assembly station for medical use

ASM has designed a special machine for assembling blood non-return valves in Paris for one of the world leaders in single-use medical equipment.

High-speed blood check valve assembly

The very high assembly and testing rate required very careful development by our engineers and technicians, particularly for the valve itself, which is more delicate to handle because it is flexible (medical silicone). In order to meet our customer's requirements, ASM used the latest high-frequency Pick & Place modules to achieve a manufacturing frequency of 2,400 parts per hour.

Technical Characteristics

- Assembly of the 2 ABS parts and the medical silicone valve

- Ultrasonic welding, flow test, tightness test and bag packaging

- Pick & Place high speeds: 2400 pieces per hour

- An independent position, with 2 hours autonomy

- SIEMENS PLC with integrated web server, allowing remote access by the customer and ASM to facilitate maintenance

ASM has designed and installed more than 300 production machines. Here are some examples of achievements that might interest you: