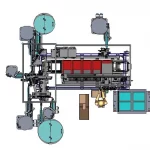

Automatic Automotive Housing Assembly Line

Automation of the Assembly of Oil Control Boxes

Assemble, check and condition gearbox oil regulation boxes according to the constraints of a German car manufacturer located in Lyon.

Principle of the assembly line

Automatic equipment driven by an operator in charge of depositing 2 components, recovering the finished products at the line outlet and packaging them.

Studies, production and installation of the equipment in 12 months - Delivery in early 2018

Average speed of 230p/h

Technologies integrated into the assembly line

- Pallet conveyor allowing the management of buffer zones,

- 7 vibrating bowls including 5 dedicated to the distribution of O-rings,

- 5 O-ring gripping pliers for removal in the component groove,

- Fittings with pressure and position management,

- Double airtightness test station under 8 bar pressure,

- Laser marking of a Datamatrix code with reading by vision camera,

- Traceability management, reconciliation and export of production data via company wifi,

- Line driving wireless touchscreen tablet.

Training of operator and maintenance personnel

ASM has designed and installed more than 300 production machines. Here are some examples of achievements that might interest you:

- Manufacturing line of thermal control boxes

- Semi-automated assembly station

- Production line with integration of 10 Universal Robots

- Automated assembly line