Packaging and Unpacking Robots

Filling, Loading and Unloading Lines

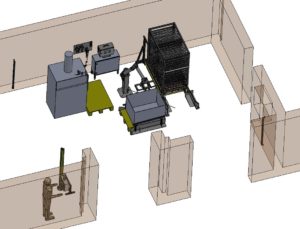

Two lines constitute the project:

- A line for filling cardboard trays and loading trolleys upstream of a steaming phase,

- An unloading line of the same trolleys at the steaming outlet.

Filling line

On the first line, the empty trays are collected from a tray tray. They are transported to a loading station in aggregates or shredded plants.

Unpacking line

On the other line, the carts filled with cardboard trays containing previously steamed shredded plant material are emptied of their boxes. The shredded material is poured into a container and the boxes are then transported to a compactor to form bales.

Project designed to meet the needs of industry in Carros.

ASM has designed and installed more than 300 production machines. Here are some examples of achievements that might interest you:

- Robotization in the food industry

- High speed ultrasonic welding cutter

- Conveying weighing and mixing perfumes

- Automatic assembly line