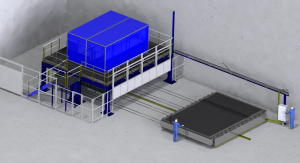

High pressure composite cooking chamber

Composite curing chamber for aeronautics

One of the world leaders in composite manufacturing has developed a revolutionary method of cooking carbon parts, drastically reducing cooking time (up to 4 times faster).

ASM, a key choice for your industrialization projects

Looking for a recognized integrator, he turned to ASM for the industrialization of his first complete industrial system. The Australian client wanted an initial installation in Germany for acceptance, followed by a final installation in Russia.

Details of our solution

- Design, calculation and sizing of the cooking chamber reception structure

- Dimensions of 8 meters by 6 meters

- Up to 300 tons of maximum pressure to withstand

- Calculation and modeling of elastic deformations related to thermal stresses

- Conveying over 20 meters of the composite mould: mobile, 12 tons, 7 meters by 5 meters

- Specific locking system to withstand the weights and pressures of the cooking chamber and above all to respect the mechanical tolerances (of the order of a millimeter)

ASM has designed and installed more than 300 production machines. Here are some examples of achievements that might interest you:

- A self-adaptive robotic screw sheathing station

- A carbon weaving line

- Packaging and unpacking robots

- Revamping with 5 universal robots of an automated storage line