Improve Precision and Productivity with ASM Automated Assembly Stations

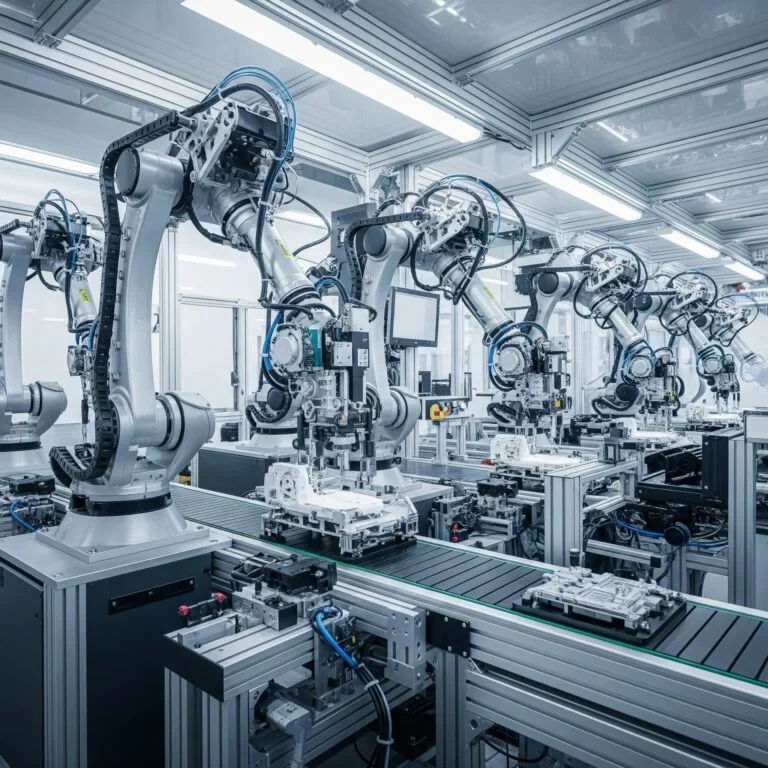

In an industrial environment demanding precision, repeatability, and efficiency, automated assembly stations are a key element in factory modernization. They optimize specific assembly operations, whether performed entirely by machines or in collaboration with an operator (semi-automated stations). ASM, an expert in automation engineering and industrial robotics, designs and integrates customized assembly station solutions, guaranteeing superior assembly quality, optimized production rates, and improved ergonomics for your operators.

Our Automated Assembly Station Solutions

We develop intelligent and efficient workstations, adapted to a multitude of assembly tasks:

- Fully Automated Workstations: Dedicated stations where all stages of the assembly of a component or sub-assembly are carried out by robotic systems and special machines, without direct human intervention.

- Integration of Automatic Screwing and Crimping: Dedicated modules for feeding and automated placement of screws, rivets, clips or for crimping operations with torque and force control.

- Integrated Quality Control: Integration of industrial vision cameras to check the presence of components, the conformity of the assembly, the correct positioning or the absence of defects, directly on the workstation.

- Automatic Loading and Unloading Systems: Solutions for supplying workstations with raw components and removing assembled products, optimizing flows.

- Traceability and Data Collection: Implementation of sensors and software to record assembly parameters (torques, forces, conformity) and ensure unit traceability of products.

The Benefits of Automating Your Assembly Stations

The integration of automated assembly stations by ASM Indus offers strategic advantages:

- Increased Productivity: Optimizing cycle times and reducing downtime, enabling targeted production rates to be achieved.

- Error and Scrap Reduction: Automation of critical tasks to minimize human error and costs associated with non-compliance.

- Improved Ergonomics and Safety: Operators are relieved of repetitive, monotonous or dangerous tasks, improving their well-being and reducing the risk of accidents.

- Control of Operational Costs: Optimizing resources and reducing indirect costs related to operator defects and fatigue.

Why Choose ASM for Your Assembly Stations?

Choosing ASM means securing an expert partnership for your assembly solutions:

- Expertise in Mechatronics: A team mastering mechanical, robotic, electrical and software integration for coherent and high-performance systems.

- User-Centered Design: Consideration of production needs, safety and ergonomics.

- Tailor-made approach: Each workstation is designed specifically for your existing operations, products, and environment.

- Complete Support: From feasibility study to installation, commissioning, training and technical support.

Contact Our Automated Assembly Station Specialists

Do you want to improve the performance and quality of your assembly operations? Contact the ASM engineers to discuss your project and design the automated assembly station that will precisely meet your industrial challenges.