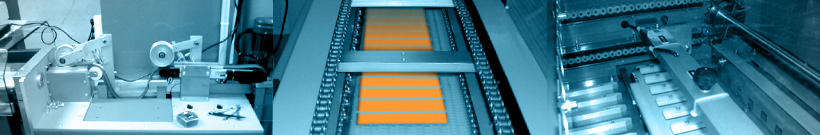

Pet food packaging machine

Automated food packaging station for fresh produce

ASM designed a machine for manufacturing animal food products (“Chews”) for one of the largest veterinary laboratories in the world located in Carros.

Objective: to automate the packaging of fresh food products

The main challenges of this project were related to the product itself. At the end of the food extruder, the product's viscosity and changing temperature made detection and handling difficult. Indeed, its composition based on natural ingredients caused dispersion of the product's moisture, thus impacting its mechanical and thermal characteristics. Thanks to feedback gained from other ASM projects, its technicians and engineers were able to overcome this problem.

Technical Characteristics of Food Packaging

- Extrusion, cutting, weighing, cooling and packaging of animal food products

- Complete management of animal health issues and agri-food standards

- Integration of Allen-Bradley PLCs

- Rate of 3000 to 6000 parts per hour

ASM has designed and installed more than 300 production machines. Here are some examples of achievements that might interest you:

- Robotization in the food industry

- Packaging and unpacking robots

- A production line with the integration of 10 Universal Robots

- Assisted handling of industrial containers