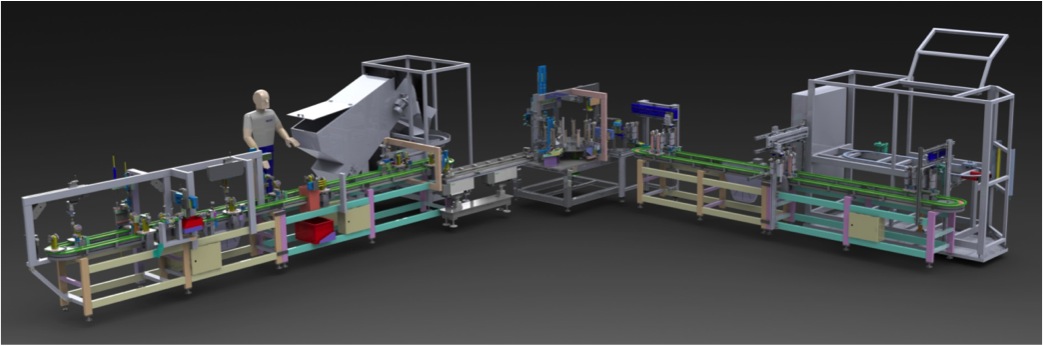

Fully Automated Line: Assembly, Testing and Assembly

Our client, the European leader in sanitary equipment from Monaco, contacted ASM to design a fully automated line for the assembly, testing and installation of flush valves.Constraints related to this line

The main challenges of this project were the management of the line layout (limited surface area, multiple posts), the production rate (5 seconds for valves made up of 14 pieces), the large number of workstations (23) as well as the management of Manufacturing Orders (several models of valves managed by the line) which involved the development of a supervision tool communicating with our client's ERP and CAPM.Features of our Assembly Line

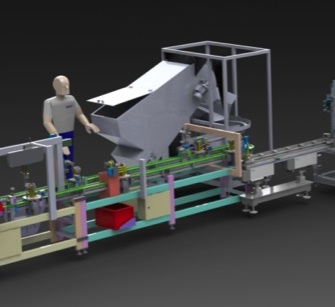

After 6000 hours of design and development, ASM delivered an assembly line with the following technical characteristics:- Fully automated production line of a faucet consisting of 14 parts

- 23 workstations on a 15m long chain

- Integration of 3 2D vision systems

- Design of a custom-made double robotic arm

- Integration of 8 UNITRONICS PLCs for the management of 23 workstations

- 1 UNITRONICS touchscreen main PLC for operator management of Manufacturing Orders, with dedicated user interface and integration with the customer's ERP

- Line output to 2 test benches in parallel, integrated into the line

- Only the supply of the hoppers, with an autonomy of 2 hours, is to be managed by the operator

- High production rates for large volumes: a valve assembled and tested every 5 seconds, i.e. 3 million valves per year

- Dedicated supervision tool developed by ASM with Dashboards / Production Management in web access

ASM has designed and installed more than 300 production machines. Here are some examples of achievements that might interest you :