Robotization of Screw Control and Sheathing

Our client, an international aeronautics group in the South West, contacted ASM to robotize the control and coating of high-performance screws used in aeronautics.

The main challenges of this project

The main challenge of this project was vision management. The interface developed by ASM had to allow operators to autonomously "teach" the machine to handle new screws. When using a new type of screw, the operators take a series of images with the vision system. Using a few parameters entered into the industrial PLC, the robot connected to the vision system is autonomous and can grasp the screw, wrap it, and then store it. It should be noted that the system developed by ASM handles screws either loose or arranged in perforated boxes as input. The output also allows for sorting by loose screw or by perforated boxes.

Technical Specifications of the Robotic Workstation

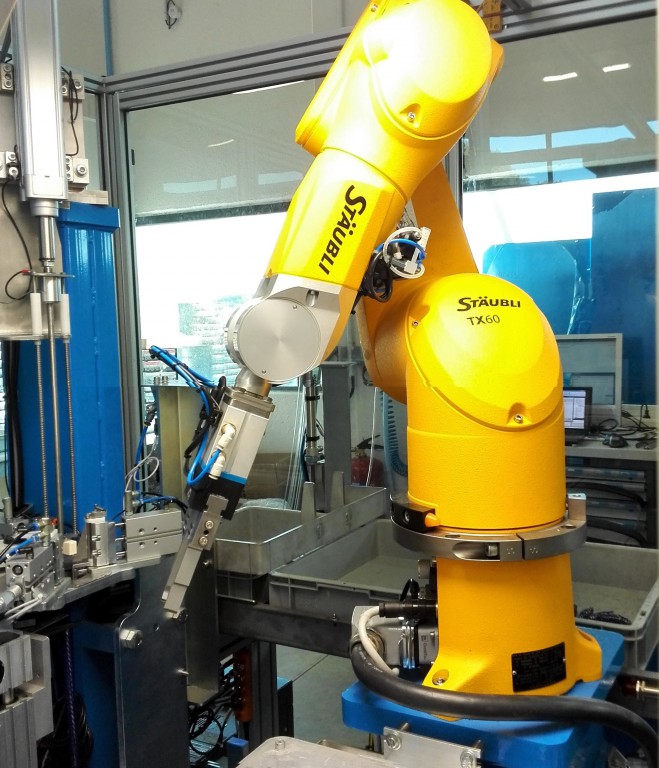

After 1500 hours of design and development, ASM delivered a robotic screw sheathing station with the following technical specifications:

- Robotic screw sheathing station (STAUBLI TX60) with integrated vision (Keyence, XG range)

- Vision-calibrated, self-adaptive machine

- System capable of handling screws up to 1.3 kg and 250 mm

- Screw recovery area of 400 mm x 300 mm

- Station cycle of 7 seconds: picking (bulk or perforated box), sheathing and dropping (bulk or perforated box)

- Maintenance with remote access via VPN

ASM has designed and installed over 300 production machines. Here are a few examples of projects that might interest you: