Curing chamber for composites used in aeronautics

One of the world's leading manufacturers of composites has developed a revolutionary method for cooking carbon parts, drastically reducing cooking time (up to 4 times faster).

ASM, a key choice for your industrialization projects

Looking for a reputable integrator, he turned to ASM for the industrialization of his first complete industrial system. The Australian client wanted an initial installation in Germany for acceptance testing, followed by a final installation in Russia.

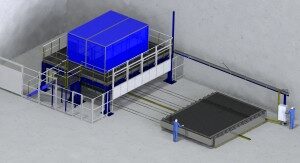

Details of our solution

- Design, calculation and dimensioning of the structure supporting the cooking chamber

- Dimensions of 8 meters by 6 meters

- Up to 300 tonnes of maximum pressure to withstand

- Calculation and modeling of elastic deformations related to thermal stresses

- Conveying of the composite mold over 20 meters: mobile, 12 tons, 7 meters by 5 meters

- A specific locking system designed to withstand the weight and pressure of the cooking chamber and, above all, to respect mechanical tolerances (on the order of millimeters).

ASM has designed and installed over 300 production machines. Here are a few examples of projects that might interest you: