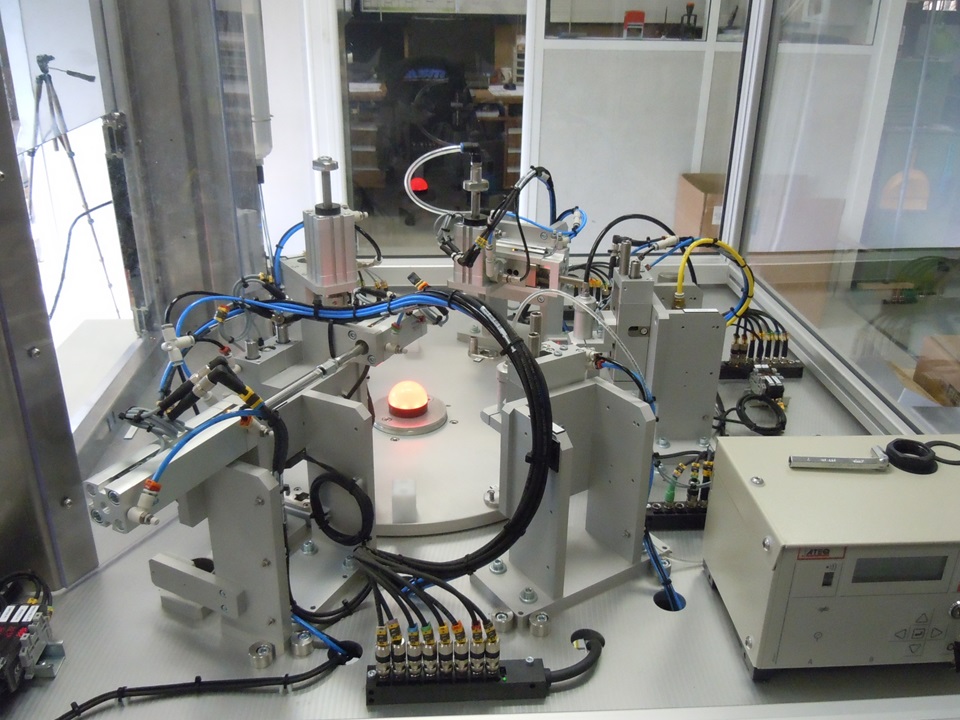

Semi-automated assembly machine for single-use medical devices

Prior to the introduction to the market of a range of innovative products for oncology, ASM carried out a pilot automated assembly and testing installation for a client located in Paris.

Objective: To validate a semi-automated assembly process for the medical field

The objective here was to validate a semi-automated assembly process for companies specializing in single-use medical equipment. The goal was to achieve an initial production rate of 600 units per hour, with the long-term objective of offering a new machine capable of reaching a rate of 3,000 units per hour, which ASM is fully capable of achieving (see another achievement). This machine is the first of its kind and now allows ASM to offer on the market a semi-automated machine for assembling connectors/sealing valves for the medical field.

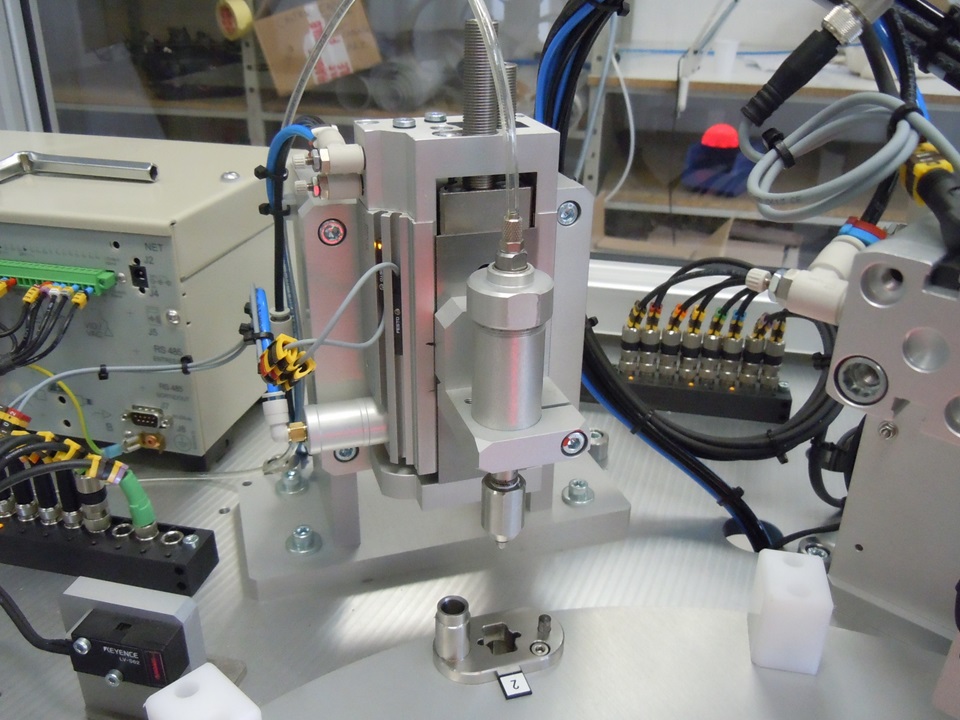

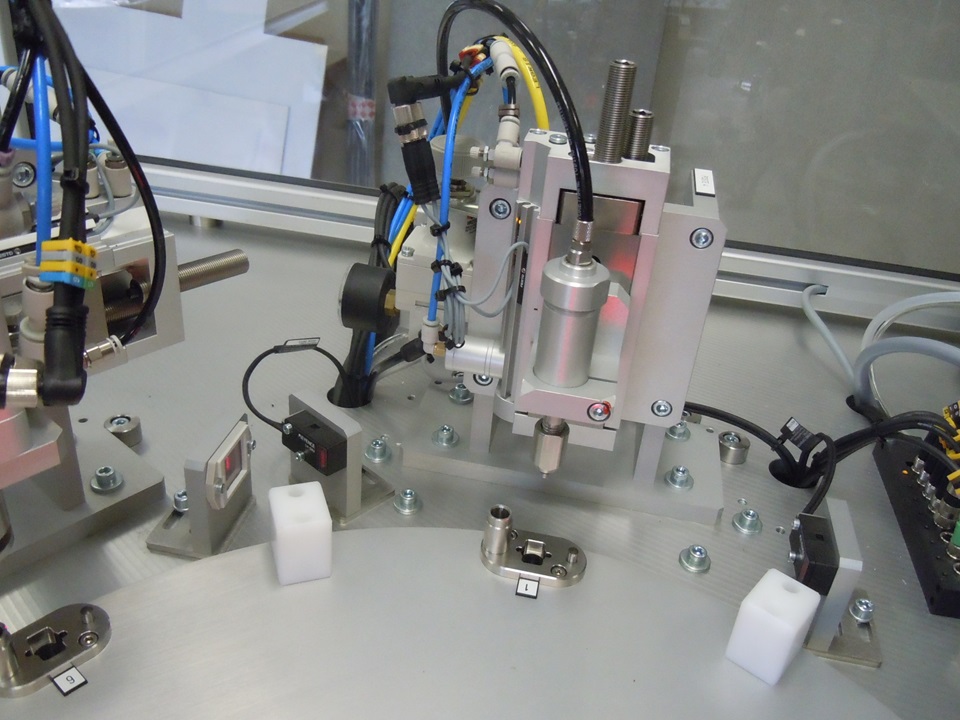

Technical Specifications Assembly Station

- Assembly of ABS parts and medical-grade silicone valve, with ultrasonic welding

- Lubrication, position test, flow test, leak test and packaging in bags

- An ergonomic workstation, handling critical precision and testing tasks

- UNITRONICS PLC with integrated web server, allowing remote access by client and ASM to facilitate maintenance

ASM has designed and installed over 300 production machines. Here are a few examples of projects that might interest you: