ASM is an engineering company creating bespoke/special-purpose machines, from semi-automatic workstations to fully-automated production lines.

As such, we are a leading player in industrial productivity, with returns on investment often less than 2 years.

With its expertise in engineering and development, ASM is your key business partner to meet your automation needs as we are experts in all stages of industrialization:

- Feasibility with our Method team to provide a “turnkey” solution

- Technical solutions by our CAD designers:

- Modeling

- Simulation

- Resistance of materials in 3D CAD

- 3D-printing (pre-testing prototypes)

- Definition of requirements by our automation team: electric, pneumatic, industrial and robotics

- Assembly, development and testing in our factory to reach specification and quality targets

- Supervision and manufacturing planning integration with ERPs and IT systems

- Facility and final acceptance on site with end-users training

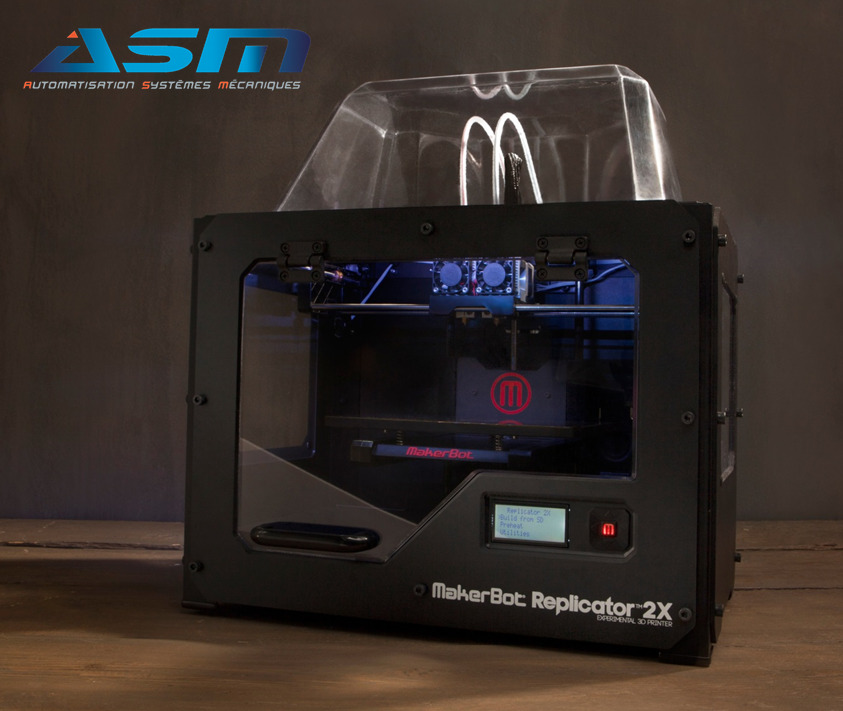

New: 3D-Printing

In order to react quickly, validate our technical solutions and test customers' prototypes in real conditions, ASM is equipped with a 3D-printer.

It is a Makerbot Replicator 2X with dual extrusion, especially made to manufacture ABS parts.

The first tests are conclusive and the parts are already used on our special machines.

![]() Our Team

Our Team

ASM engineers and technicians have a simple goal: to provide the technical solution or service that best meets customer requirements in terms of cost, time and quality.

- Business managers: with their strong technical knowledge, they will innovate and offer unique solutions to meet your needs of bespoke machines.

- Research department: both in Mechanical and in Automation, our team is composed of professionals with experience in both manufacturing and production. These skills allow them to design robust machines (simple, with reduced cost and easy maintenance), while meeting the needs required by large volumes.

- Technicians: with the experience gained in recent years on projects in various technologies, they assemble your machines on site and ensure that your operators and technicians are trained to better optimize your production.

![]() Our Sectors

Our Sectors

Since its inception, ASM has voluntarily been working in multiple areas. This allows our engineers to address any queries and transfer technical solutions to new fields of application. This “outside-the-box” approach allows our team to find creative, innovative and cost-efficient solutions.

Examples:

|

|

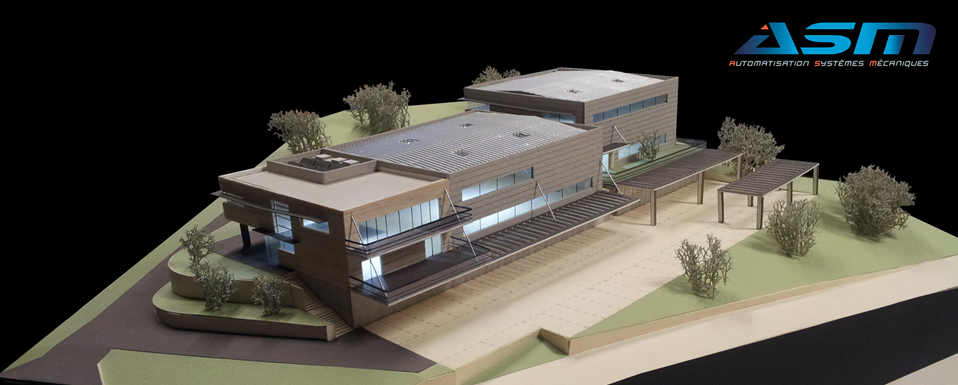

Headquarters (2014)

As of 2014, ASM welcomes you in its new head office of 1400m² in Sophia Antipolis, FRANCE:

- A building dedicated to special-propose machines: (1st tranche in 2014)

- An R&D area of 300m²

- A workshop of 500m² with 6m high ceiling for larger installations

- Located in the heart of the Sophia Antipolis Science Park

- A Highly Energy Efficient Building “Effinergie +”: energy optimization, geothermal energy, solar panels…