Automated storage and testing in ATEX-certified test tubes for the oil industry

Our client, a leading global energy company located in the South of France, contacted ASM to design a fully automated machine dedicated to testing petroleum products. Such a product did not exist, and until ASM developed this equipment, petroleum companies lacked dedicated testing equipment for petroleum derivatives.

Project constraints

Working directly with the client's research and development teams, ASM engineers had to take into account numerous requirements related to the product being tested:

- The footprint had to be minimized to accommodate the test ovens, which were placed on the floor in a laboratory with limited space.

- Versatility of the installation, as several sizes of test tubes are used: 25 ml, 50 ml, 100 ml and 250 ml

- The test tubes must be airtight for the validity of the tests.

- Fully automated test management, with durations ranging from a few hours to several days.

Line Features

After 2000 hours of design and development, ASM produced a line with the following technical characteristics:

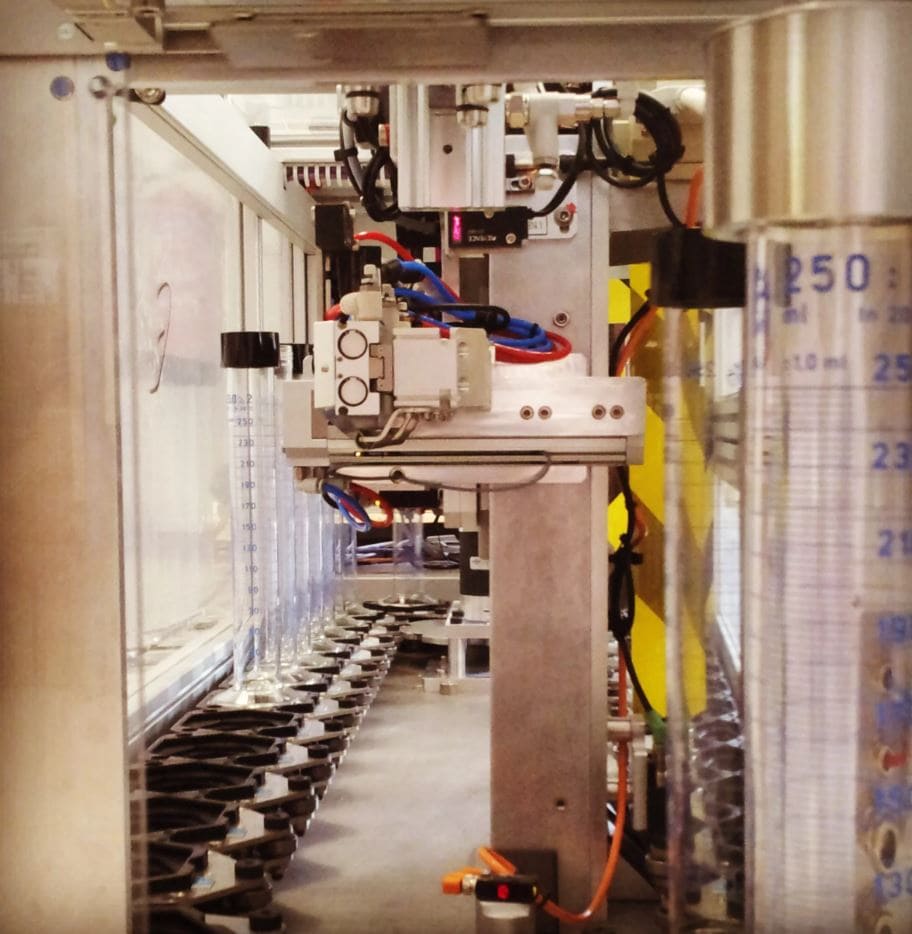

- Testing and storage of 30 hermetically sealed test tubes on a conveyor belt

- A specially designed robotic arm that combines pneumatic cylinders and electric motors

- Maximum miniaturization through integration of the robotic arm into the center of the test tube conveyor.

- Versatility of the system, dynamically managing different specimen formats

ASM has designed and installed over 300 production machines. Here are a few examples of projects that might interest you: